System integration enabling multi-system connection and communication and offering harsh environment mechanical integrity, electrical reliability, connectivity and communication flexibility and agnostic integration.

Tensor Collar Connection System

Tensor Drilling Technologies is dedicated to enabling healthy competition in markets where our customers could not previously penetrate. This continues with the Tensor Collar Connection System – an innovative solution allowing the mechanical and electrical connection of any number of downhole collar-based tools and integration onto the Tensor downhole M/LWD platform. The low-cost, high reliability system delivers seamless connection between MWD probes, LWD collars and/ or rotary steerable systems [RSS].

With this proven solution Tensor Drilling Technologies have redefined system integration enabling multi-system connection and communication at a fraction of the cost of traditional integration projects. The system is designed to bring standardization and reliability to the three foundations of any downhole system connection:

Mechanical Integrity

Building on the recognition as the M/LWD supplier of choice in high temperature, high vibration operations the Tensor Collar Connection System delivers the reliability that the industry demands. All components use the Tensor Rotary Interface which guarantees the most robust of connections while maintaining ease of use. 175 ºC/ 347 ºF and 20,000 psi specification is standard. The system requires no special collars or collar connections allowing BHA design to be prioritized to ensure success in any operating environment.

Electrical Reliability

All inter-module/ inter-collar connections are made with the proven high temperature Rotary Connectors used throughout the Tensor M/LWD platform. Industry leading reliability and vibration resistance assure connectivity in even the harshest of environment.

Communication Flexibility

Downhole tools from different providers use a range of communication protocols which are often incompatible. By leveraging many years of integration experience Tensor now offers out-of-the-box communication between the Tensor qBUS and any third-party system communication protocol slashing any integration time to a minimum.

Integrated Flexibility and Reliability

The Tensor Collar Connection System is a low-cost, highly reliable system that delivers seamless connection between MWD probes, LWD collars and/ or rotary steerable systems [RSS]. The system features:

Simple, Reliable Make-up

By relying on only a single connection to be screwed and torqued each interface can be made with negligible risk of damage and minimal impact on rig operations.

Easily Serviceable

As with all Tensor Drilling Technologies products the Collar Connection System has been designed to enable easy service and test. Service kits and tooling are available for all components.

Standard Collars

Flexibility in system configuration means that no special collars, or collar connections, are required to house the System modules.

Agnostic Integration

By maintaining qBUS as the System protocol, and translating third-party data on to the qBUS, any number of communication protocols can be managed in the same string.

![]()

System Components

POGO

The POGO module is a rugged extendable module accommodating 10”/ 250 mm of extension to allow the connection of any two modules or collar interfaces either in the workshop, on the deck or on the rigfloor. Standard Tensor Rotary Connectors both uphole and downhole make connection simple, quick and reliable. The latest sealing technology ensures reliable performance in the most extreme conditions.

The POGO houses the Translator Board in its downhole chassis.

Translator

The Translator Board controls the communication between the Tensor qBUS and any third-party system. The Board is assigned a Node Address on the qBUS allowing direct communication for surface testing and programming. Firmware controls the communication protocol between the qBUS and the third-party system and so by changing settings the same board can be used to communicate with multiple different third-party systems.

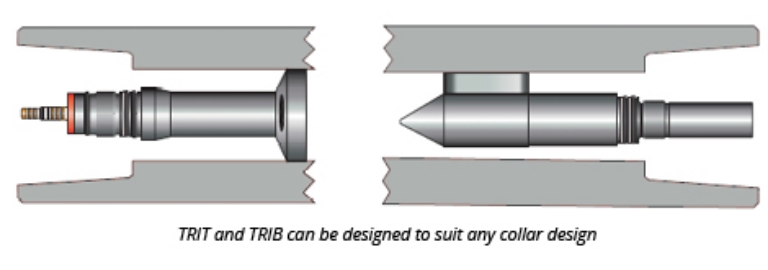

Rotary Interconnect Interfaces

Collar-based tools are dressed with Tensor Rotary Interface Top [TRIT] and/ or Tensor Rotary Interface Bottom [TRIB]. These Interfaces carry the Tensor or third-party wiring to the Tensor system probe module by way of the standard Tensor Rotary Connectors. Tensor Drilling Technologies can design bespoke TRIBs/ TRITs to suit any collar design.

Wire Through Modules

To increase flexibility in BHA design, and reduce the requirement for non-standard collar lengths, Wire Through Modules are available. These simple modules are available in a range of sizes to allow the toolstring to be extended to accommodate sensor spacing or BHA design requirements.